Present Projects We Can Discuss On The Web Site

The projects discussed here are my own projects and

therefore I control the release of information about them. Client

project data

is carefully

guarded and released only with client permission and is not available on this site. I work with clients to create unique systems and concepts and invite your

expressions of interest in letting me find solutions to your problems.

(click on photos to enlarge them)

A

major activity I am pursuing in my own projects is the development of

new energy sources and new types of instrumentation technology.

There are proposals currently submitted from clients to which I will

contribute my services in developing unique technology applications to

provide more energy, more easily controlled, to users.

A

major activity I am pursuing in my own projects is the development of

new energy sources and new types of instrumentation technology.

There are proposals currently submitted from clients to which I will

contribute my services in developing unique technology applications to

provide more energy, more easily controlled, to users.

We can provide a unique range of abilities for your unique projects.

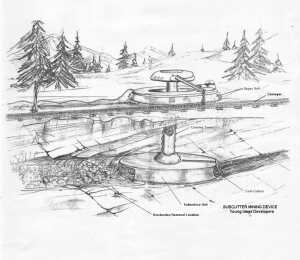

The "Sub Cutter" is a device which seems a contradiction of terms

- a strip miner for coal or tar sands which does not disturb the surface vegetation or

strata! It is not possible to give a detailed description of all engineering

functions in this web site but in principle the machine removes a seam or bed

down to about 15 meters below the surface by using somewhat conventional

coal or other mining machines mounted in the front of the circular lower portion

of the machine under computer control and using television cameras allowing

the operators on the surface to control the cutting operation.

The "Sub Cutter" is a device which seems a contradiction of terms

- a strip miner for coal or tar sands which does not disturb the surface vegetation or

strata! It is not possible to give a detailed description of all engineering

functions in this web site but in principle the machine removes a seam or bed

down to about 15 meters below the surface by using somewhat conventional

coal or other mining machines mounted in the front of the circular lower portion

of the machine under computer control and using television cameras allowing

the operators on the surface to control the cutting operation.

Material which is not coal or other material is cut and pushed to the back of the machine while the desirable material is taken on a conveyor to a vertical conveyor which sends it up the "conning tower" and out to waiting conveyors or trucks.

Waste material from the mining operation is forced out the back of the machine by hydraulic rams and the machine itself slowly pushes itself forward while the conning tower rotates to drag material in front to the rear, and the surface unit also pulls the conning tower forward. Machine stresses in the conning tower are controlled by stress sensors which do not allow bending stresses to build up in the tower.

As the machine moves forward, the area behind it collapses to fill the void left by the removal of the coal. Material such as "spent" tar sands can also be disposed of by sending it down the rotating conveyor belt and sequestering the material behind the Subcutter. Material above the Subcutter lower body will also collapse often on the machine, but the machine is capable of moving ahead under this load as well. This is a very powerful machine and will be costly, but no more so than the large machines now used in open pit mines.

The environmental advantages of this machine are, we believe huge as with appropriate auxiliary machines even trees could be removed and replaced as the subcutter passes by and the small disturbance the tower makes can be easily restored and reseeded. America has gigantic beds of coal and other materials which can serve as an energy source and a source for industrial chemicals which are now embroiled in various legal proceedings and Subcutter will allow us to "have our cake and eat it too" by providing surface mining all can live with.

This is an example of Young Ideas view that any problem can be solved with enough ingenuity!

The Sub Cutter is a very large undertaking and will require many investors and a large amount of work which we cannot complete by ourselves. We would serve as technical and creative advisors as was done on the Natural Bridges Solar Plant We invite your interest in this environmentally sound idea as the world needs more energy to reduce dependence on oil.

There is an ongoing effort to develop cost effective photovoltaic

systems for Indian and other families. Recent elections in India

have shown the desire of the poor in India to share in the growing

Indian economy and electricity for rural homes and villages will be a

great challenge. Where our work will lead is as yet unknown, but

there are many expandable applications for systems which can begin with

low cost, minimal performance and as funds allow, expand to larger,

more capable systems in a "plug and play" concept we are working on.

This is a cost effective application for PV

systems which is not being addressed because of bureaucracies, poor designs,

and several other problems. We are working to solve these problems.

There is an ongoing effort to develop cost effective photovoltaic

systems for Indian and other families. Recent elections in India

have shown the desire of the poor in India to share in the growing

Indian economy and electricity for rural homes and villages will be a

great challenge. Where our work will lead is as yet unknown, but

there are many expandable applications for systems which can begin with

low cost, minimal performance and as funds allow, expand to larger,

more capable systems in a "plug and play" concept we are working on.

This is a cost effective application for PV

systems which is not being addressed because of bureaucracies, poor designs,

and several other problems. We are working to solve these problems.

guarded and released only with client permission and is not available on this site. I work with clients to create unique systems and concepts and invite your

expressions of interest in letting me find solutions to your problems.

(click on photos to enlarge them)

A

major activity I am pursuing in my own projects is the development of

new energy sources and new types of instrumentation technology.

There are proposals currently submitted from clients to which I will

contribute my services in developing unique technology applications to

provide more energy, more easily controlled, to users.

A

major activity I am pursuing in my own projects is the development of

new energy sources and new types of instrumentation technology.

There are proposals currently submitted from clients to which I will

contribute my services in developing unique technology applications to

provide more energy, more easily controlled, to users.We can provide a unique range of abilities for your unique projects.

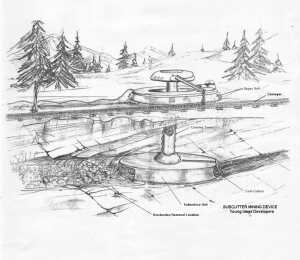

The "Sub Cutter" is a device which seems a contradiction of terms

- a strip miner for coal or tar sands which does not disturb the surface vegetation or

strata! It is not possible to give a detailed description of all engineering

functions in this web site but in principle the machine removes a seam or bed

down to about 15 meters below the surface by using somewhat conventional

coal or other mining machines mounted in the front of the circular lower portion

of the machine under computer control and using television cameras allowing

the operators on the surface to control the cutting operation.

The "Sub Cutter" is a device which seems a contradiction of terms

- a strip miner for coal or tar sands which does not disturb the surface vegetation or

strata! It is not possible to give a detailed description of all engineering

functions in this web site but in principle the machine removes a seam or bed

down to about 15 meters below the surface by using somewhat conventional

coal or other mining machines mounted in the front of the circular lower portion

of the machine under computer control and using television cameras allowing

the operators on the surface to control the cutting operation.Material which is not coal or other material is cut and pushed to the back of the machine while the desirable material is taken on a conveyor to a vertical conveyor which sends it up the "conning tower" and out to waiting conveyors or trucks.

Waste material from the mining operation is forced out the back of the machine by hydraulic rams and the machine itself slowly pushes itself forward while the conning tower rotates to drag material in front to the rear, and the surface unit also pulls the conning tower forward. Machine stresses in the conning tower are controlled by stress sensors which do not allow bending stresses to build up in the tower.

As the machine moves forward, the area behind it collapses to fill the void left by the removal of the coal. Material such as "spent" tar sands can also be disposed of by sending it down the rotating conveyor belt and sequestering the material behind the Subcutter. Material above the Subcutter lower body will also collapse often on the machine, but the machine is capable of moving ahead under this load as well. This is a very powerful machine and will be costly, but no more so than the large machines now used in open pit mines.

The environmental advantages of this machine are, we believe huge as with appropriate auxiliary machines even trees could be removed and replaced as the subcutter passes by and the small disturbance the tower makes can be easily restored and reseeded. America has gigantic beds of coal and other materials which can serve as an energy source and a source for industrial chemicals which are now embroiled in various legal proceedings and Subcutter will allow us to "have our cake and eat it too" by providing surface mining all can live with.

This is an example of Young Ideas view that any problem can be solved with enough ingenuity!

The Sub Cutter is a very large undertaking and will require many investors and a large amount of work which we cannot complete by ourselves. We would serve as technical and creative advisors as was done on the Natural Bridges Solar Plant We invite your interest in this environmentally sound idea as the world needs more energy to reduce dependence on oil.

There is an ongoing effort to develop cost effective photovoltaic

systems for Indian and other families. Recent elections in India

have shown the desire of the poor in India to share in the growing

Indian economy and electricity for rural homes and villages will be a

great challenge. Where our work will lead is as yet unknown, but

there are many expandable applications for systems which can begin with

low cost, minimal performance and as funds allow, expand to larger,

more capable systems in a "plug and play" concept we are working on.

This is a cost effective application for PV

systems which is not being addressed because of bureaucracies, poor designs,

and several other problems. We are working to solve these problems.

There is an ongoing effort to develop cost effective photovoltaic

systems for Indian and other families. Recent elections in India

have shown the desire of the poor in India to share in the growing

Indian economy and electricity for rural homes and villages will be a

great challenge. Where our work will lead is as yet unknown, but

there are many expandable applications for systems which can begin with

low cost, minimal performance and as funds allow, expand to larger,

more capable systems in a "plug and play" concept we are working on.

This is a cost effective application for PV

systems which is not being addressed because of bureaucracies, poor designs,

and several other problems. We are working to solve these problems.